Rebar is usually a standard metal bar or block that is definitely greatly used in reinforced concrete and bolstered masonry structures. These rebars are frequently established from carbon metal and can be recounted as reinforcing steel or just reinforcement. Under Structural BIM Expert services Rebar detailing is mostly a self-control of constructing fabrication or store drawings of steel reinforcement to your development approach. The site fabrication drawings which are created according to design and style drawings for reinforcing metal are Rebar Detailed drawings. Engineers and Architects make layout drawings to convey about the required strengths based upon the rebar detailing that provides diameter, bar shapes, quantities, volume of bars to aid the website for averting delays and wastage thereby speeding your entire building course of action.

Each individual rebar is thorough representing a form, length, and diameter depending on the necessities Along with the layout drawing. The Rebar placement will then be demonstrated in better detail which signifies the concrete go over, precise site, and Specific method of placement as necessary. The rebar particulars and bar bending schedules may have bar diameter, bar notation, the level of bars, weight during the bars, and duration of Each and every bar along with mentioning the general excess weight for the total list of bars placed within drawing. Throughout the preparation of rebar specifics, the stock lengths of bars are saved in watch so as that there is totally no wastage from the material.

Rebar Detailing and Reinforcement concrete detailing can now be modeled and designed in three-dimension Using the 3D Modelling technology like BIM Modelling Products and services. The specialized rebar detailing program like Rebar CAD and AutoCAD utilized for this intent may well assistance each member of the structural engineering to organize layouts, document, keep track of, and Over-all control.

Having comprehended the essential strategy of rebar detailing a piece of structural BIM modeling, why Never we try and comprehend the worth of it in the general construction system is. Some within the explanations are:

Relevance of Rebar detailing in Structural BIM Modeling

While 2D drawings and bending schedules are commonly produced and presented, the 3D design is usually issued to all the team members commencing the consulting engineer and contractor departments all the way down to the metal fixers that happen to get Along with the walk-out on-site. The mixture of All those two turn out to be Specially helpful for internet site staff where by web-site limitations or congestion of reinforcements stay unidentified till you will find reinforcement and fixation on site. For each bar, the entire place of repairing is revealed Within the 3D design in conjunction with any hindrances or obstructions.

Building detailing reinforcements in 3D inside the second approach is not only more rapidly but modeling rebar inside a 3-dimensional atmosphere can help take out clashes. Although modeling one can maybe visualize if any of your bars tend to not repair that has a determined place, thereby recognize these clashes throughout the rebar read more drawings. There is Probably the facility to examine the reinforcement in full depth becoming a specific detail illustration just before it remaining staying ordered inside the fabricator and complicated cages are assembled off-web page.

When you may have the suitable rebar detailing Remedy offered, a reliable and correct reinforcement product might be produced by importing structural calculations within the structural analysis application. With Automation associated modifications is often reflected inside the 3D rebar detailing and needed updates to drawings and schedules swiftly when changes are manufactured in other places as opposed to obtaining to accomplish manual variations to 2D sections and sights.

As an alternative to depending on manual input from paper schedules, the rebar fabricator can extract facts directly with the model for the machinery. The concrete pours may be very well-outlined while in the design with other information like quantities and volumes To make certain far more precision in controlling material deliveries. This will permit higher Handle and result in much less wastage and minimize in Total prices.

Possessing 3D in-depth digital versions will not likely restrict the edge to a single-section like that within the engineering and detailing section but is often used inside the phases. Having reinforcement absolutely modeled in 3D, the contractor is certain that it will quickly fit into places when the time arrives it to be mounted on-web page. The information from a product may very well be utilized inside of area allowing for contractors to perform a design-primarily based format from the use of robotic total station devices in conjunction with monitoring rebar and supplies and identifying area they're going to be demanded.

Fixers present on-internet site seems to be while in the model environment with the rebar detailing to accurately understand its application, i.e. what is expected the place and when as opposed to relying on their interpretation of classic second drawings.

The structural engineers can unquestionably plus more immediately generate style and design stories, schedules, and drawings in the 3D design in comparison with 2D layouts, therefore maximizing layout efficiency. There may be more accuracy on cost projection Based on the rebar portions manufactured from the 3D model given that They may be extra reputable in comparison with second drawing get-offs. Not just this the portions are wholly traceable, enabling comparisons and checks to acquire done effortlessly.

Using these factors, we are able to conclude that Rebar Detailing a self-control of Structural BIM Modelling Products and services is just one With all the essential requirements for your Over-all accomplishment with the job everyday living cycle. To summarize, owning Rebar Detailing the rebar contractor can give full attention to creating rebars where there are going to be no should really estimate reinforcement demands for procurements at your internet site resulting from productive 3D types. The model will depict the need of anchors and laps In the drawings therefore guaranteeing structure adequacy together with lowering wastage. The overall waste and time delays are reduced at the location because all the shape drawings is often offered. Based on this data the bars is likely to be very easily fabricated determined by the shapes and quantity of bars expected.

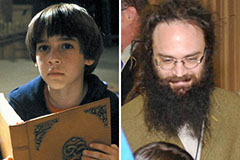

Barret Oliver Then & Now!

Barret Oliver Then & Now! Tiffany Trump Then & Now!

Tiffany Trump Then & Now! David Faustino Then & Now!

David Faustino Then & Now! Raquel Welch Then & Now!

Raquel Welch Then & Now! Christy Canyon Then & Now!

Christy Canyon Then & Now!